Milan – October 31st, 2019

As part of the continuous effort to drive standardization and industry-shared value in Vendor Management, SupplHi is collaborating with leading Association and international Players in defining the Guideline for industry-shared Supply Chain Assessment in Plant Engineering industries (Oil & Gas, Chemicals, Power, Renewables, Shipbuilding, Steel & Metals, Cement, …).

SUPPLY CHAIN SUSTAINABILITY

Sustainability is a broad concept, with different applications by industrial vertical and by type of supply of equipment and service.

In general terms, Sustainability is defined as the development that meets the needs of the present without compromising the ability of future generations to meet their own needs. The concept of Sustainability – for the purposes of the Guideline – is composed of three pillars (ESG): Environmental (“E” – covering Energy Efficiency, Pollution and Waste Management) Sustainability, Social (“S” – covering Equal Opportunities, Human Rights, Working Conditions, Local Content) Sustainability and Governance (“G” – covering Ethics, Anticompetitive practices, Responsible Information Management, Sustainable Procurement) Sustainability.

RELEVANCE FOR PLANT ENGINEERING INDUSTRIES

The Plant Engineering industries – due to their large incidence on the global GDP and due to the technical knowledge required in the supply of equipment and services – always had a particular focus on Environmental, Social and Governance aspects in their day-by-day businesses. In fact, Sustainability has always been a value present across the Plant Engineering Supply Chain and it is becoming increasingly relevant, now representing – rather than only a compliance and company duty – an added-value opportunity for differentiation in the global competition.

In the Plant Engineering industry, Supply Chain has a strong incidence and can represent up to 80% of a Buyer organization’s revenues. A Buyer organization is considered as Sustainable only if its Supply Chain is considered as Sustainable. Therefore, Supply Chain Sustainability requires a constant Assessment of the practices of Buyer’s Vendors.

The Plant Engineering industries are characterized by very complex supply chains – involving large players as well as SMEs.

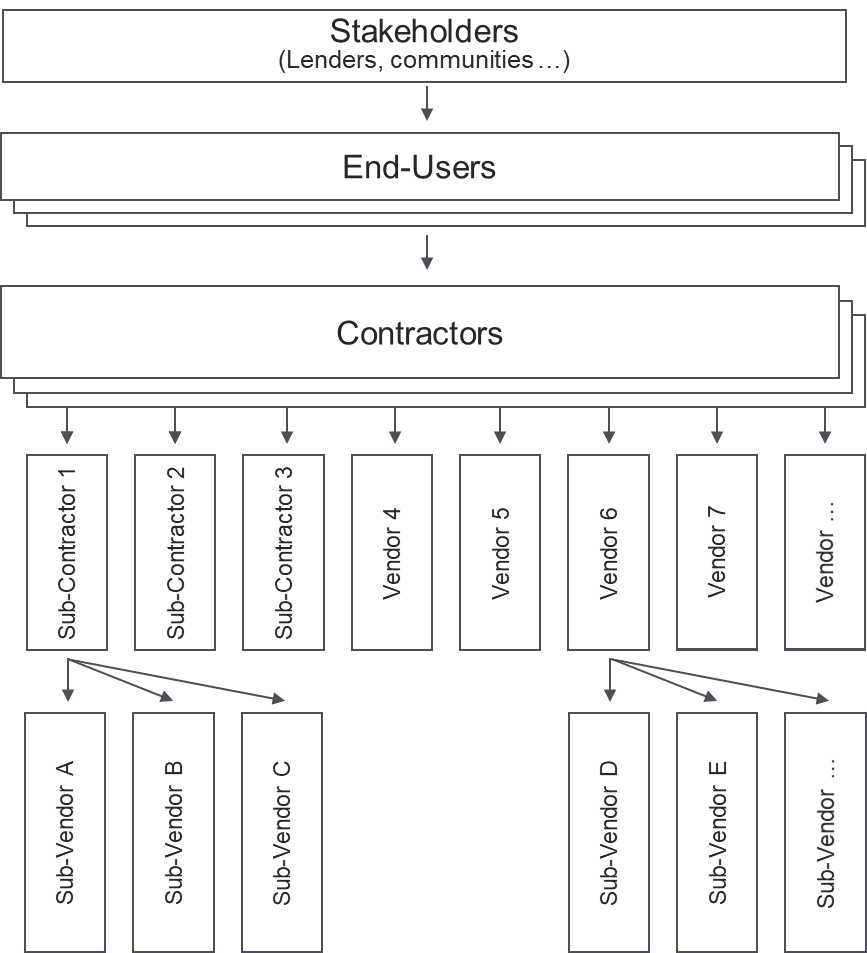

As a consequence, Supply Chain Sustainability is a pass-through across the entire Supply Chain and the Assessment involves:

- Stakeholders (e.g. Lenders, local communities, …);

- End-Users (e.g. Oil & Gas companies, Renewable operators, …);

- Contractors (the main company-ies responsible for the engineering, procurement and construction of a Plant Engineering project);

- Sub-Contractors (e.g. construction companies, …)

- Vendors (e.g. manufacturers of valves, pumps or providers of engineering services, …)

- Sub-Vendors (e.g. foundries, forges, …).

Furthermore, the Supply Chain of Plant Engineering industries is typically very global and spread across continents, being at first subject to the local and international legislations in terms of ESG requirements.

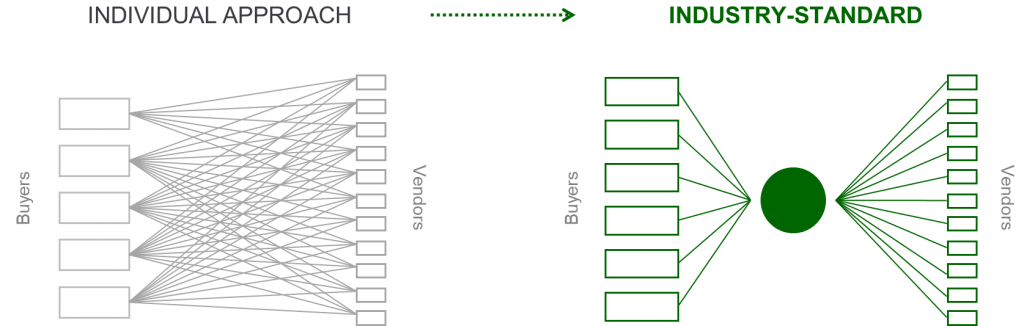

WHY A GUIDELINE THAT STANDARDIZES

Individual approaches in Supply Chain Sustainability Assessment in the Plant Engineering industries so far prevailed, generating inefficiency for the industry and to all players involved. Individual approaches require each Buyer organization to collect information on Sustainability from Vendors, to create metrics for Assessment and to monitor and constantly update the information from Vendors.

In fact, the global Plant Engineering industry was lacking a Guideline for Supply Chain Sustainability Assessment that is based on an:

- industry-specific standard;

- industry-shared platform.

While larger players have higher level of awareness and dedicated functions for Sustainability – also due to the obligations to produce Sustainability Reports, SMEs are still lagging behind in terms of dedicated internal presidium while trying to better comply and give evidence of their Sustainability practices.

INTERNATIONAL REFERENCES

Several international references on Supply Chain Sustainability are already present in the Plant Engineering industry and can support the Assessment of Supply Chain Sustainability. However, each of existing international reference is focused on some specific aspects, partially covering the full requirements of the Supply Chain Sustainability spectrum that requires the collection of information from multiple sources with reference to different standards.

- Standards, Norms and Certifications, e.g.: SA 8000 on Social Accountability; ISO 14001 on Environmental Management; ISO 26000 on Social Responsibility; ISO 45000 or OHSAS 18001 on Occupational health and safety; ISO 50001 on Energy Management; ISO 37001 on Anti-bribery Management.

- Programs, e.g.: UN Sustainability Development Goals (SDG) and UN Global Compact; GRI Global Reporting Initiative; Circular Economy 100 (CE100) – Ellen MacArthur Foundation for Circular Economy.

- NGOs, Super-national Bodies, International Organizations involved in the topic (e.g. OECD, World Bank, Eco-Label Européen, International Labor Organization, United Nations Environment Program, …).

- Taxonomies (e.g.: European Commission’s EU Technical Expert Group on Sustainable Finance, …)

- Associations providing guidance (e.g. IPIECA, …).

THE ANIMP WORKGROUP FOR STANDARDIZATION

In September 2019, ANIMP – the Italian Association of Industrial Plant Engineering, acting as a meeting point of key industry players with common needs and leveraging on its network of internationally renewed companies, people, skills and researchers in the field of Plant Engineering – created a dedicated Workgroup composed by international EPC Contactors, Large OEMs, SMEs and SupplHi as solution provider aimed at the creation of a Guideline for the Assessment of Supply Chain Sustainability in the Plant Engineering industries.

The Guideline has the objective to define the recommended set of information and assessment metrics – to assess the Sustainability of a Supply Chain in the Plant Engineering industries. Furthermore, the Guideline aims at further raising the level of awareness on Sustainability practices across all the layers of the Plant Engineering Supply Chain.

OBJECTIVES OF THE WORKGROUP FOR STANDARDIZATION

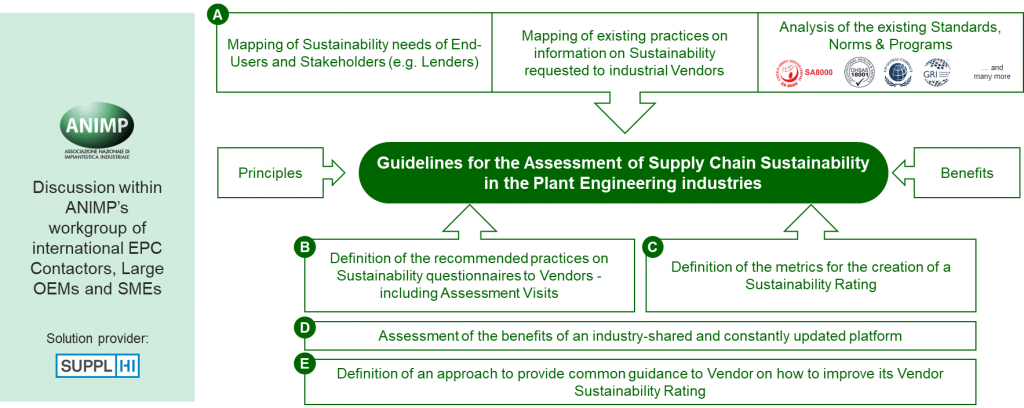

The workgroup – mainly composed by Sustainability Managers and in collaboration with the Vendor Management departments of main international EPC Contractors – performed, across multiple meetings and interactions, the following activities:

-

Mapping of the current Sustainability requirements by End-Users to Contactors and of existing standards and norms available on the market as well as benchmarking of the existing practices of 100+ international Buyer organizations on Sustainability questionnaires to Vendors;

-

Based on an agreed set of Principles, definition of the recommended practices on Sustainability questionnaires to Vendors – including the Assessment Visits to verify most critical Vendor Sustainability aspects – relevant for the different categories of supply;

-

Definition of the metrics for the creation of a Sustainability Rating as an industry-standard and industry-shared evaluation of a Vendor in the Plant Engineering industries;

-

Assessment of the benefits of the industry-shared and constantly updated SupplHi Vendor Management platform that hosts information on Vendor questionnaire, Assessment Visits (also produced by independent third parties) and Sustainability Metrics;

-

Definition of an approach to provide common guidance to Vendor on how to improve its Vendor Sustainability Rating and sharing of recommended Sustainability practices to Vendors, with focus on SMEs.

BENEFITS OF AN INDUSTRY-SHARED GUIDELINE ON SUSTAINABILITY ASSESSMENT

An industry-shared Guideline on Supply Chain Sustainability Assessment, specific the Plant Engineering industries, presents multiple benefits for all the actors involved:

Benefits driven by the industry-specific standard effect:

- Access to the Sustainability information relevant to the Plant Engineering industries;

- Avoid the costly creation and maintenance of an internal Sustainability Assessment model;

- Reduce risks and increase the transparency on Sustainability across the entire Supply Chain;

- Stronger compliance based on an industry-specific model.

Benefits driven by the industry-shared platform effect delivered by SupplHi:

- Reduce costs for the individual collection of Sustainability information from Vendors

- Prompt access to information when required, due to Vendors already invited by other Buyers or self-candidate to the industry-shared Sustainability Assessment;

- Increase compliance through the quality assurance by an independent third party of the information on Sustainability made available by Vendors, including the constant expedite of updates.

NEXT STEPS

The completion of the review and dissemination of the Guideline is expected by January 2020. The Guideline will be constantly open to comments and improvements.

For enquires related to the Guideline being elaborated, please contact SupplHi at info@supplhi.com.

For an overview of the Supply Chain Sustainability module on SupplHi’s SaaS, please refer to the following links: