Milan, September 16th, 2021

On September 16th, Giacomo Franchini, Director of SupplHi jointly presented a journey on innovation with Pilar Molina, Group Supply Chain Digitalization & Group Vendor Management Head of Department from the Maire Tecnimont Group at Digital Procurement World 2021.

During the 25-minutes session titled “Setting the standard in supplier management through industry collaboration” attended live by over 140 Procurement Professionals, the following points were touched upon:

- The 10 common pain points in Supplier Management apply in the form of Efficiency losses and Compliance risks

- Business Case model with 40%+ savings from SupplHi, delivered faster than initially thought

- Servitization model based on microservices, beyond any traditional Supplier Management practice

- Innovation is not additive but subtractive, eliminating redundancy and complexity

- Platform + Standardization + Servitization + Network = SupplHi

- Industry knowledge is fundamental and sophisticated Customers are the best co-designers

- Processes need to be always all based on Compliance-by-design

- SupplHi as digital backbone for the industry through its Open Innovation

Below is the original video of the event followed by a transcript of the entire speech:

About DPW Conference:

DPW Conference is an annual technology event held in Amsterdam, Netherlands, and considered the world’s largest and most influential tech event of the procurement industry. Now in its second year, DPW Conference has grown to over 3,000 attendees and become a crossroads for the world’s largest buyers and sellers of procurement technology, alongside many of the world’s most disruptive emerging technology companies.

Setting the Standard in Supplier Management through Industry Collaboration,

by Pilar Molina and Giacomo Franchini

Pilar Molina: Hello everybody, thanks for this opportunity and thank you all for joining this session. May I introduce myself: I am Pilar and I’m the Head of Business Support, Vendor Management and Supply Chain Digitalization at the Maire Tecnimont Group. I have 20+ years of experience on IT implementations and business processes design with a particular focus on Supply Chain.

It’s more than 10 years that I work at the Maire Tecnimont Group, a large EPC contractor for industrial plants for Petchem, Fertilizer, O&G and Power. We work with both, hydrocarbons, and green energy. Our purchases in 2020 were more than 2.5 billion euros, leveraging on a base of 30.000 suppliers.

For this session we have selected a public LinkedIn video done after March 2020 COVID’s emergency to show what we do in the Engineering, Procurement and Construction business and, above all, our main asset that are our people and their entrepreneurial vision.

(Click to watch the full video)

(Click to watch the full video)

As you’ve seen, we deliver large plants all over the world. Maire Tecnimont is Supply Chain, and we rely on our partners & suppliers to deliver technologically driven plants.

In this context, Supplier Management is paramount for our business.

Giacomo Franchini: Thank you Pilar, and hello everybody. My name is Giacomo Franchini, Founder and CEO at SupplHi.

So, why Supplier Management matters so much?

First of all, in industrial B2B purchases contribute – on average – to more than 50% of a company’s revenues, directly impacting the bottom line. The Supplier base is a real chain, global, highly fragmented and made of thousands of suppliers – not only the large corporations but mainly Small and Medium Enterprises that, in some cases, are the real engine.

As a consequence, Buyers require constant visibility on who does what and how good is that supplier. Qualification and performance evaluations are must-have processes – in many cases prescribed by the quality management certifications – while, ESG Sustainability – including carbon emission – compliance and risk monitoring have been quickly escalating in relevance.

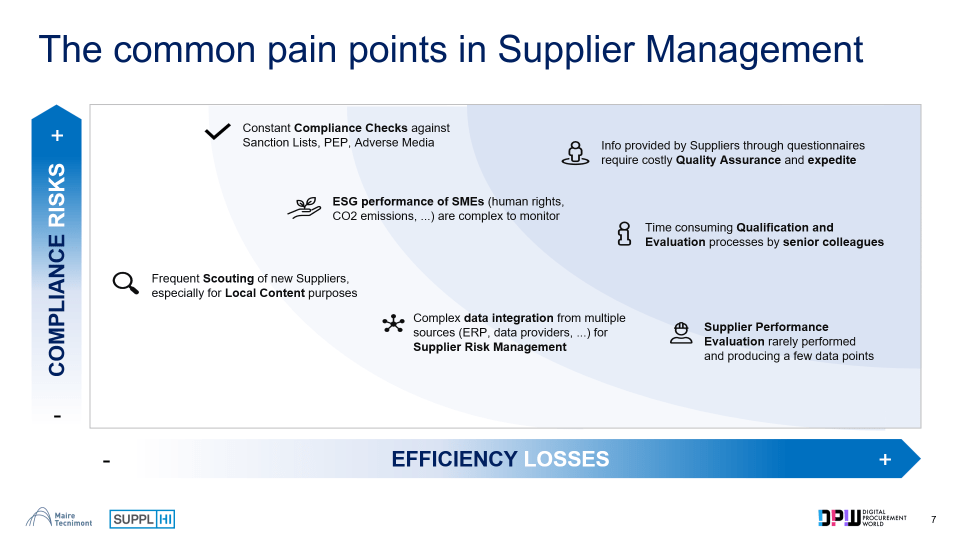

In this context, a series of pain points in Supplier Management typically apply in the form of Efficiency losses and Compliance risks.

First, Buyers need information that is not public, and they collect it from Suppliers through expiring questionnaires. Who takes care of the Quality Assurance and of the constant expedite of this valuable information? How are you going to sustain the 100 euro/hour of opportunity cost on the lengthy Qualification and Evaluation processes that involve your senior colleagues? How to get the most out of Supplier Performance Evaluations that are rarely performed and that produce only a few data points in an age where data is the new petroleum?

It’s not only about efficiency, but it’s a lot about Compliance: the checks against Sanction Lists, PEP, Adverse Media need to be constantly performed, while the ESG performance of suppliers – such as human rights, CO2 emissions and water management among the others – are extremely complex to monitor, especially on SMEs.

Last but not least, frequent Scouting of new Suppliers – especially for Local Content purposes – absorb precious energies while complex data integration from multiple sources – such as ERP and data providers – jeopardize Supplier Risk monitoring efforts.

Pilar Molina: Thank you Giacomo. So, all of these pain points were ours. A rigid model, HW obsolescence, growing requirements on an ever-changing environment for a fast-growing company.

How did MET tackle the problem?

The MET approach has 2 concepts embedded in its 3-year Digital program to unlock the hidden potential of new solutions: moving from the IT implementation of pure software to the delivery of Services that create value to the business. And to effectively measure this, each project has a supporting Business Case that is periodically monitored: we do not only measure CAPEX and OPEX but also the ROI of the new Services.

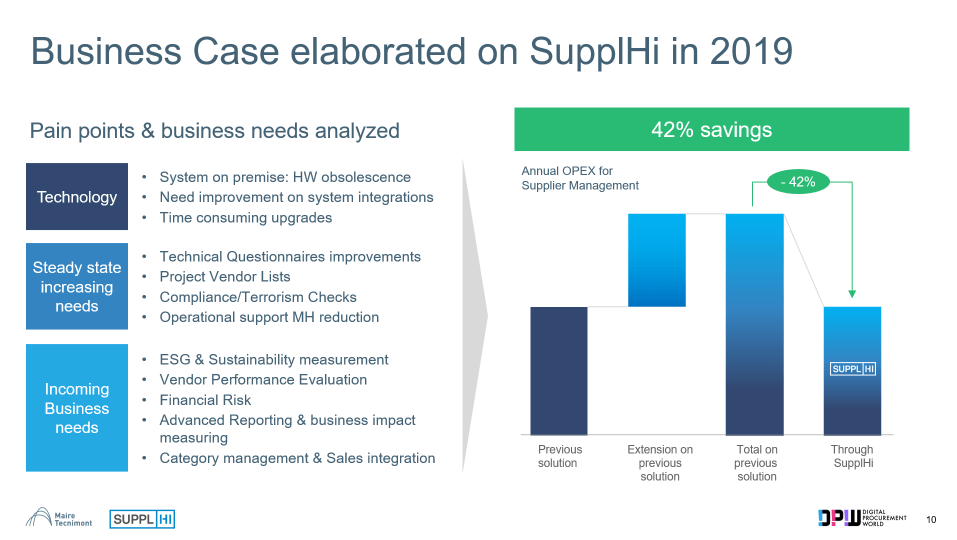

In 2019, we have applied this approach to Supplier Management activities.

Knowing the pain points, the needs’ backlog, and the new business requirements here we illustrate the Business Case model and the +40% savings that the implementation of a dedicated service based on an industry model is providing to our Group of 50 operating companies.

The results after 18 months are more than encouraging. I refrain a MET motto: our future is now.

We have built a strong partnership with SupplHi, and MET service-oriented approach to business, combined with a highly tuned backend and delivery model on the SupplHi side, unlocked fast track value and – to be honest – faster than we initially thought.

The new service approach allowed the upskilling of the internal resources, reducing clerical works at their minimum in order to better focus on the new business services.

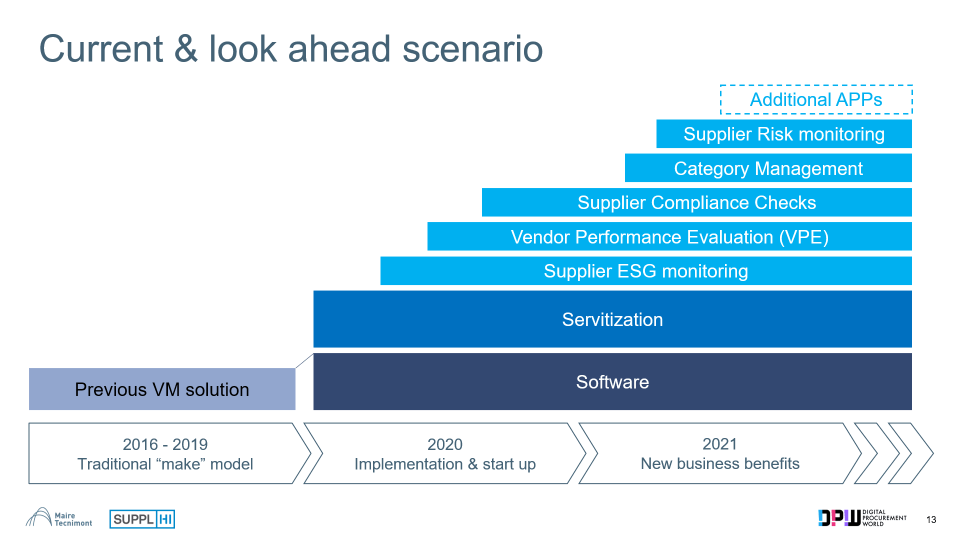

I will not go deep on the servitization model & strategy but on how the knowledge contamination from service industry, such as the IT – unknown to the EPC business – can be unconventionally applied to activities such as Supply Chain and, in this case, Supplier Management. Well beyond any traditional model.

How? Structuring microservices.

Decomposing our polymers to work on the single atoms as solid, self-standing building blocks, therefore reassembling them, innovating on the delivery, and providing growing, faster and better services. Eliminating redundancy and complexity. As when we recycle plastic in our plants.

Innovation for us is not additive but subtractive.

On one side, the innovation by addition is tangible. It demonstrates activity and when asked the inevitable question, what are you doing to improve innovation? answers are easy and visible: meetings, champions, deliverables.

Instead, we approached innovation inverting the problem. Subtractive innovation is not easy: it requires out-of-the-box thinking and simplifying what you are currently doing by dismissing processes that no longer add value.

Always in full compliance with procedures and policies, including the cybersecurity ones.

Our ship sailed away from a traditional MAKE scenario to the implementation & start-up of a new service model.

We are not done yet: add ins & enhancements are in pipeline, some of them regarding increasing anticorruption compliance checks, other ones linking the Vendor Performance Evaluation to HR MBOs of the middle management.

We consider data as the new petroleum and the ultimate objective is to have a real time risk monitoring model of all our most critical Suppliers.

Thanks, Giacomo please drive us through your journey to deliver an unconventional solution and service delivery model that allowed the Maire Tecnimont Group to go beyond any traditional Supplier Management practice.

Giacomo Franchini: Thank you Pilar. I will now explain how all of this has been made possible through the SupplHi SaaS that is based on four pillars that strengthen each other:

- Firstly, SupplHi is a secure and modern SaaS with a triple ISO Certification;

- Secondly, we embed efficient and compliant Supplier Management processes based on the best international practices and that are standard, yet highly configurable;

- Thirdly, SupplHi is not only just a platform but also a Service that takes care of supplier disambiguation, quality assurance, expedite of info and much more, for example the digitalization of vendor lists;

- Furthermore, SupplHi operates by B2B verticals with Buyers sharing the same needs and willingness to drive efficiency across their supplier base.

In synthesis, by using a secure platform that is based on standardization of industry processes and that embeds servitization, Buyers can also enjoy the benefits of a Network effect.

Let’s now go deeper on each of these 4 pillars.

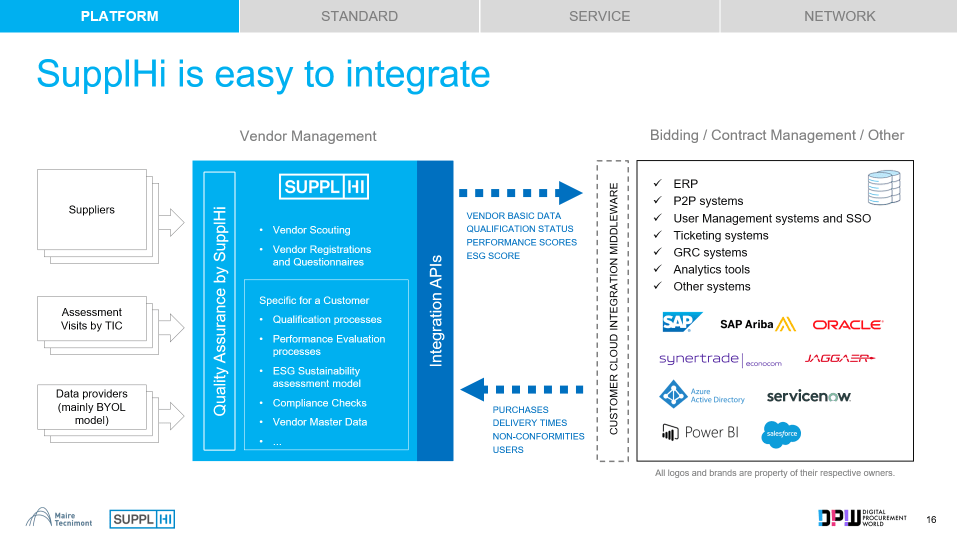

On the Platform side, SupplHi is a modular and one-stop-solution, covering – in a single Platform – all Supplier Management needs from Vendor Register, Scouting, Qualification, Performance Evaluation to Vendor ESG Sustainability, Compliance Checks, Vendor Assessment Visits and Supplier Risk monitoring.

Customers select the APPs that they need the most and seamlessly grow over time, for additional benefits.

SupplHi is upstream to other Procurement processes and easily integrates with any system.

In the case of the Maire Tecnimont Group we have integrated SupplHi with SAP, SAP Ariba, Azure Active Directory for SSO, ServiceNow and Salesforce.

Moreover, SupplHi acts as the Vendor Master Data and Golden Record for the entire Group.

In fact, through a modern set of APIs, the Vendor basic data, Qualification statuses, Performance Evaluation and ESG scores are exported to Customers’ ERP and P2P systems.

Finally, SupplHi integrates with data providers such as BVD, D&B among the others.

On the Standard the Performance Evaluation has never been easier and more comprehensive, with standard root causes and evaluation processes that are specific for B2B industries and that run in parallel with the lifecycle of the most critical supplies.

The standard applies also to the questionnaires to Suppliers.

SupplHi – through servitization – takes care of vendor disambiguation, quality assurance, expedite of information – letting Buyers and Vendors save time and money.

Data Providers and information collected by assessors are also integrated in a single solution.

The Qualification process is highly configurable for a specific organization, and it allows to saves time of the senior colleagues.

Approved Vendor Lists are automatically maintained up to date, increasing compliance by dismissing excel or word files.

All these best-of-breed functionalities of SupplHi could have been part of a traditional solution, with an individual platform that is costly and time consuming for all. As you can see from this spaghetti network, we love pasta but not for these procurement processes.

The SupplHi vision – instead – has been to digitally connect the global industrial supply chains by shifting directly into an industry-shared platform, with savings for both Buyers and Vendors.

Again, we innovated by subtracting and not by adding.

Currently, through its Network, SupplHi hosts information on over 62.000 Suppliers covering 110 geographies over the span of 2.600 standard categories of supply.

Registered Vendors are associated to a Single Supplier Digital Identity, providing information once for many Buyers and adding TRUST and transparency to the entire Supply Chain. It is very important to mention that SupplHi is free-of-charge for any supplier, being inclusive and easy to adopt.

Vendors gain further visibility not only through a horizontal Network, but also through a vertical network of End Users, Contractors, Service Providers and Manufacturers. It is also important to remember that any Vendor is also a Buyer of sub-supplies.

How have we made SupplHi possible? The mantras that are sustaining our rapid growth are:

- Industry knowledge is fundamental

- Our sophisticated Customers are our best co-designers

- Processes are all based on Compliance-by-design

- It is not just an APP. We have built a business & service model enabled by the best-of-breed Technology Stack as an enabler.

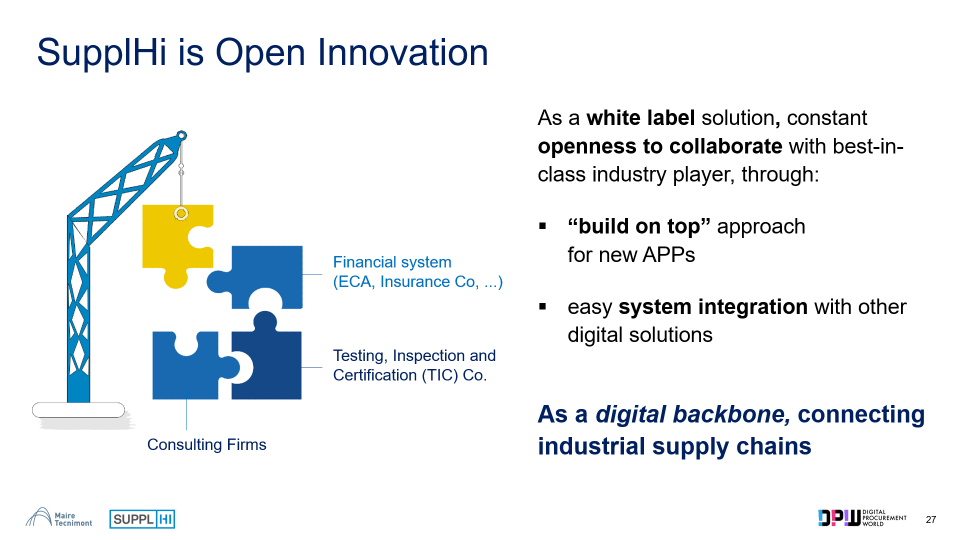

As we have emphasized during this session, collaboration and Open Innovation are key aspects at SupplHi.

As an independent solution provider, we have constant openness to collaborate with best-in-class industry player, through the build-on-top approach for new APPs and through enhanced integrations with other digital solutions.

Nowadays, we are more and more collaborating with the Banking and Insurance system – including Export Credit Agencies – on ESG monitoring and Risk Management, with Info Providers and Consulting Firms and with the leading Testing, Inspection and Certification companies.

Now you have a better understanding on how we are creating value in Supplier Management.

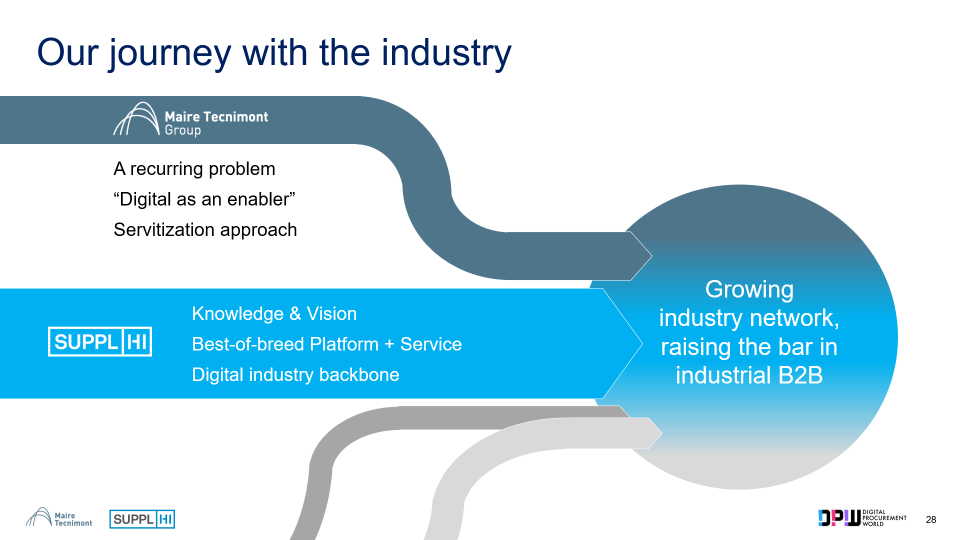

On our side: SupplHi’s industry-shared approach, knowledge and standardization is instrumental to constantly improve our best-of-breed platform and to couple it with enhanced services. Collaborations is based on SupplHi as a digital backbone for the industry.

On the other side: the journey with the Maire Tecnimont Group is based on their pragmatic approach and ability to look at their processes with new lenses: they wanted to solve a recurring problem with a digital as an enabler approach, and with a clear ROI. Servitization delivered faster-than-expected efficiency and more compliant processes.

It is just the beginning for more to come with them, with the industry and for the industry.

The growing industry Network follows as a consequence – raising the bar in critical supply chains – with benefits to the Buyers and to the many Suppliers on platform.

We really want to thank you for your kind attention. A special thanks to Pilar and to Maire Tecnimont Group for your continuous trust along the years and for your contribution to today’s event

Please, feel free to reach out to us for any clarifications and for more opportunities together.